NASA Engineers’ Triumph: Overcoming JWST Design Flaws

The James Webb Space Telescope’s journey to operation involved overcoming a critical design flaw, a testament to the ingenuity and unwavering dedication of NASA engineers who leveraged their expertise to ensure its success.

Delving into the intricate world of space engineering, we uncover the fascinating, often untold, stories behind humanity’s greatest scientific endeavors. Few tales exemplify problem-solving under pressure quite like the insider knowledge: the untold story of how NASA engineers overcame a critical design flaw in the James Webb Space Telescope, a monumental achievement that pushed the boundaries of astrophysics.

The Genesis of a Giant: JWST’s Grand Ambition

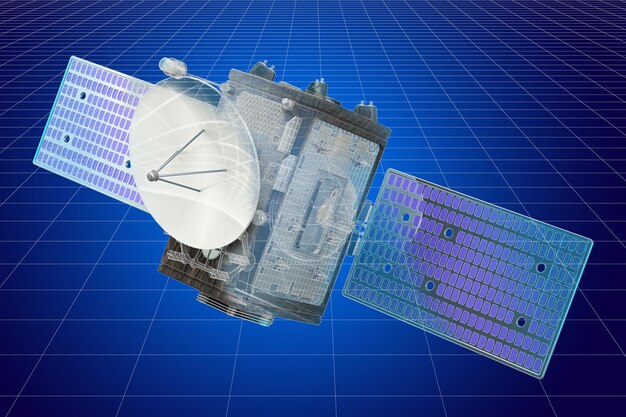

The James Webb Space Telescope (JWST) was conceived as a revolutionary successor to the Hubble Space Telescope, designed to peer further into the universe than ever before. Its primary mission involved observing the first galaxies, studying exoplanet atmospheres, and unraveling the mysteries of cosmic origins. This grand ambition, however, came with unprecedented engineering challenges. The sheer scale and complexity of the telescope, particularly its enormous segmented primary mirror and tennis-court-sized sunshield, demanded innovative design solutions and meticulous execution.

From its earliest conceptualization, the JWST faced an uphill battle. Developing cutting-edge technology always presents unforeseen obstacles, but the Webb was in a league of its own. NASA and its partners, the European Space Agency (ESA) and the Canadian Space Agency (CSA), envisioned an instrument capable of capturing infrared light, which would allow it to penetrate cosmic dust clouds and observe distant, ancient astronomical objects. This necessitated cryogenic cooling and an incredibly precise, deployable mirror system, two areas ripe for potential design complications.

Early Design Hurdles and Revolutionary Concepts

The initial design phases of the JWST were marked by intense scientific debate and engineering innovation. Scientists pushed for capabilities that engineers had to translate into tangible, functional components. The decision to use a segmented, deployable mirror, for instance, was revolutionary. Unlike Hubble’s single, monolithic mirror, JWST’s mirror is composed of 18 hexagonal segments made of beryllium, each coated with a thin layer of gold to optimize infrared reflectivity. This design choice allowed for a much larger collecting area while still fitting within the launch vehicle’s fairing.

- Segmented Mirror: Enabled a larger aperture, critical for collecting faint infrared light.

- Cryogenic Cooling: Essential to reduce background infrared radiation from the telescope itself.

- Sunshield Design: Maintained extreme cold temperatures by blocking solar radiation.

- Launch Vehicle Constraints: Mandated a complex, origami-like folding mechanism for deployment.

These early decisions, while brilliant in their conception, embedded inherent complexities that would later manifest as critical engineering challenges. The integration of mechanical, optical, and thermal systems into a single, cohesive unit required a level of precision and interdisciplinary collaboration rarely seen in space exploration projects. The foundation for both its astounding success and its most daunting design flaw was laid during these foundational years, years characterized by ambitious goals and the painstaking work of turning abstract concepts into concrete designs.

The journey from concept to reality for a project of JWST’s magnitude is never linear. It involves constant iteration, rigorous testing, and the inevitable discovery of unforeseen issues. The early design phases were critical in defining the scope and nature of the challenges ahead. It was a period of both immense intellectual excitement and the quiet, persistent diligence that underpins every successful space mission.

Unveiling the Achilles’ Heel: The Sunshield Anomaly

One of the most critical components of the James Webb Space Telescope is its five-layer sunshield, designed to protect the mirrors and instruments from the sun’s heat, allowing them to cool to cryogenic temperatures. This massive, intricate structure, roughly the size of a tennis court, was always recognized as a potential point of vulnerability due to its complex deployment mechanism and the ultra-thin, delicate material of the membranes. It was during extensive ground testing that an unexpected and significant design flaw emerged, specifically related to the sunshield’s tensioning system.

Engineers discovered that the cabling system responsible for pulling the sunshield layers taut was experiencing unexpected slack and bunching. This wasn’t merely a minor alignment issue; it threatened the very ability of the sunshield to deploy correctly and, consequently, the telescope’s capacity to reach and maintain its operational temperature. Without a perfectly tensioned sunshield, the scientific instruments would be too warm to detect the faint infrared signals from the early universe, effectively rendering the telescope useless. The implications were profound, potentially delaying the mission by years and incurring significant additional costs.

Understanding the Root Cause

Identifying the precise root cause of the sunshield’s tensioning problem was a paramount challenge. The sunshield consists of five Kapton membranes, each as thin as a human hair, separated by vacuum gaps. These layers are pulled into a fixed shape by a series of motor-driven cables and pulleys. The initial analysis revealed that thermal expansion and contraction, combined with subtle manufacturing deviations in the cables and the deployment mechanisms, were leading to the slack observed during testing in a vacuum environment. The environmental conditions on Earth, even in specialized clean rooms, could not perfectly replicate the zero-gravity and extreme temperature differentials of space, making anomaly detection challenging.

- Thermal Effects: Non-uniform cooling/heating of cables caused differential contraction/expansion.

- Manufacturing Tolerances: Minor deviations in cable length and pulley alignment compounded the issue.

- Deployment Sequence: The order and timing of tensioning motors exacerbated the slack.

- Material Properties: Unforeseen behavior of Kapton and cables under microgravity and temperature extremes.

The engineers faced a daunting task: how to fix a flaw in a system designed for space, where intervention after launch is impossible. The problem required a deep dive into the physics of materials, the mechanics of complex cable systems, and the intricate choreography of autonomous deployment sequences. It was a classic “needle in a haystack” scenario, with the added pressure of billions of dollars and decades of dreams riding on their ability to pinpoint and resolve the issue.

The discovery of this critical flaw illuminated the inherent risks in space exploration. Every component, no matter how small, plays a vital role, and a slight miscalculation or unexpected material behavior can jeopardize an entire mission. This became a defining moment for the JWST team, shifting their focus from assembly to an intensive, high-stakes diagnostic and problem-solving endeavor.

The Elite Task Force: Assembling the A-Team

Upon the identification of the sunshield tensioning anomaly, NASA and its contractor, Northrop Grumman, wasted no time in assembling an elite task force. This was not a typical committee; it was a highly specialized “A-Team” comprised of the most brilliant and experienced engineers, material scientists, and thermal experts from across the agency and industry partners. The diverse expertise of this group was critical, as the problem spanned multiple engineering disciplines: mechanical, thermal, materials science, and systems engineering.

The task force operated with an unprecedented level of urgency and collaboration. Regular, often daily, meetings were held to share data, discuss hypotheses, and scrutinize every possible variable. Communication channels were streamlined, bypassing bureaucratic layers to facilitate rapid decision-making. This environment fostered intense intellectual sparring, where every assumption was challenged, every test result questioned, and every potential solution rigorously debated. The stakes were incredibly high, and the pressure immense, but the team’s dedication to the mission transcended personal agendas.

Multidisciplinary Approach to Problem Solving

The problem presented by the sunshield was not confined to a single domain, necessitating a truly multidisciplinary approach. Mechanical engineers dissected the cable routing and pulley systems, searching for friction points or misalignments. Thermal engineers simulated the temperature distributions across the sunshield layers in space, trying to model the minute expansions and contractions that could cause slack. Material scientists examined the Kapton membranes and the cables themselves under various stress and temperature conditions, looking for unforeseen properties or degradation. System engineers integrated all these findings, attempting to build a comprehensive model of the sunshield’s behavior during deployment.

- Mechanical Engineering: Analyzed cable pathways, pulley designs, and motor synchronization.

- Thermal Analysis: Modeled temperature gradients and their impact on material dimensions.

- Materials Science: Investigated properties of Kapton and cable materials under space conditions.

- Software Development: Updated deployment algorithms to compensate for observed anomalies.

This holistic approach was pivotal. Each discipline contributed a piece of the puzzle, and it was the synthesis of these individual insights that ultimately led to a clearer understanding of the flaw. The team utilized advanced simulation tools, extensive re-testing in vacuum chambers, and even developed new analytical models to untangle the complex interplay of forces and thermal effects acting on the sunshield. It was a race against time, with every day of delay costing millions and pushing the launch window further away.

The assembling of this “A-Team” showcased NASA’s ability to mobilize its intellectual capital in times of crisis. It reinforced the notion that complex engineering problems require comprehensive, collaborative solutions, driven by the brightest minds available. Their shared commitment to the success of the James Webb Space Telescope became the driving force behind their rigorous pursuit of a solution.

Innovation Under Pressure: The Corrective Measures

With the root causes of the sunshield tensioning flaw identified – primarily subtle issues related to thermal expansion and contraction of the tensioning cables exacerbated by manufacturing variations – the elite task force embarked on developing corrective measures. This phase was characterized by intense innovation and rigorous testing, as any proposed solution had to be flawless, given the impossibility of repair in space. The engineers explored multiple avenues, from hardware modifications to software adjustments, meticulously evaluating each for efficacy and potential unintended consequences.

The primary solution centred on modifying the operational deployment sequence and introducing a more robust tension management system. Instead of relying solely on pre-programmed motor commands, the revised approach incorporated real-time feedback mechanisms and a more iterative tensioning process. This involved a series of small, controlled tensioning “pulls” that would gradually stretch the sunshield layers into their correct positions, allowing for passive thermal adjustment and ensuring uniform tension across all five membranes. This adaptive approach was a significant departure from the original, simpler deployment plan.

Tailored Solutions and Rigorous Testing Regimes

The team engineered several crucial adjustments. Firstly, an updated software algorithm was developed to control the deployment motors with higher precision and allow for pauses between tensioning cycles. This allowed the Kapton membranes to thermally stabilize and for any slack to naturally mitigate through small adjustments. Secondly, minor modifications were made to the cable routing system to reduce friction points and ensure smoother movement during deployment. Thirdly, a new, more comprehensive ground testing regimen was put in place to simulate a wider range of thermal conditions and deployment scenarios than previously conducted, pushing the system to its limits to validate the proposed fixes.

- Adaptive Tensioning Algorithm: Allowed for precise control and pauses in deployment.

- Friction Reduction: Optimized cable pathways and pulley surfaces.

- Enhanced Ground Testing: Introduced new thermal vacuum tests mirroring space conditions more closely.

- Material Pre-stressing: Investigated methods to pre-condition materials to reduce post-deployment shifts.

One particularly ingenious solution involved leveraging the very thermal properties that caused the initial problem. Engineers devised a strategy to slightly warm certain sections of the sunshield cables during deployment using heaters, inducing a controlled expansion that would temporarily alleviate tension in areas prone to bunching. This allowed the system to settle more effectively, and once the heaters were turned off, the cables would contract, pulling the sunshield taut. This delicate dance of heating and cooling, synchronised with motor movements, ultimately ensured the sunshield’s proper tensioning.

Every proposed modification was subjected to an excruciating level of scrutiny and simulation. Physical mock-ups were built, and every component was re-tested individually and as part of the integrated system. The iterative nature of this problem-solving process—design, test, analyze, refine—was key to its success. The engineers demonstrated incredible resilience and ingenuity, transforming a mission-critical flaw into a testament to their problem-solving capabilities under immense pressure. Their collaborative spirit and unwavering focus on detail were central to overcoming what many saw as an insurmountable hurdle.

The Deployment Drama: Nail-Biting Moments in Space

After years of meticulous design, rigorous testing, and the critical flaw resolution, the James Webb Space Telescope finally launched on December 25, 2021. However, the journey was far from over. The most intricate and risk-laden phase of the mission lay ahead: the autonomous deployment of its complex structures, particularly the delicate five-layer sunshield. This was a process designed for perfection, spanning two weeks, and executed remotely from Earth, with no possibility of human intervention.

The deployment of the sunshield alone involved 139 release mechanisms, 70 hinge assemblies, 400 pulleys, and 90 cables, all interacting seamlessly to unfurl the massive heat shield. Each step was a potential point of failure, and the entire world watched with bated breath as updates trickled in from mission control. Engineers on the ground, who had spent years troubleshooting the sunshield anomaly, were acutely aware of the potential for the past problems to resurface. These were truly nail-biting moments, as the unfolding of the sunshield represented the single greatest risk to the mission’s success.

Real-time Monitoring and Contingency Planning

The team at mission control employed sophisticated telemetry systems to monitor every aspect of the deployment. Thousands of sensors on the telescope provided data on temperature, position, and tension in real time. Engineers meticulously analyzed this data, comparing it against their models and contingency plans. Every slight deviation, every unexpected reading, triggered intense discussions and rapid response from dedicated teams. Their extensive experience with the sunshield’s past issues proved invaluable, as they could interpret subtle signs that might otherwise have gone unnoticed.

- Sensor Data Analysis: Constant monitoring of temperature, position, and tension.

- Model Comparison: Real-time data against predicted deployment behavior.

- Contingency Readiness: Pre-planned responses for various potential anomalies.

- Team Readiness: 24/7 staffing with engineers intimately familiar with every system.

There were moments of genuine concern. During one phase of sunshield tensioning, telemetry showed that motors were drawing slightly more power than expected, indicating potential friction. The team had practiced for such scenarios during simulations, and their experience from overcoming the design flaw allowed them to confidently pause the deployment and assess the situation. After careful analysis, they determined that the issue was minor and transient, likely due to subtle thermal shifts, and proceeded with the deployment sequence. Such moments highlighted the invaluable nature of their “insider knowledge” gained through overcoming previous hurdles.

The successful unfurling of the sunshield on January 4, 2022, was met with widespread relief and jubilation. It was more than just a mechanical triumph; it was a testament to the dedication, resilience, and ingenuity of the engineers who had devoted years, if not decades, to designing, building, and, crucially, repairing this marvel of engineering. The drama of the deployment reaffirmed that even with the most extensive planning, space exploration remains an endeavor filled with inherent risks, overcome only by human brilliance and perseverance.

Lessons Learned: A Blueprint for Future Missions

The experience of identifying and overcoming the critical sunshield design flaw on the James Webb Space Telescope provided invaluable lessons that extend far beyond this single mission. It served as a powerful case study in complex systems engineering, risk mitigation, and collaborative problem-solving. The insights gained are already shaping the approach to future large-scale space exploration projects, particularly those involving intricate, autonomously deploying structures and instruments operating in extreme environments.

One of the most significant takeaways was the paramount importance of thorough and iterative testing, pushing components and systems to their absolute limits under simulated operational conditions. Not just in a factory, but in truly representative thermal and vacuum environments. The discovery of the sunshield flaw, despite extensive testing, underscored that even minor environmental discrepancies during ground tests can mask critical issues that will emerge in the vacuum of space. Future missions are now incorporating even more aggressive and comprehensive pre-flight testing protocols designed to uncover such subtle, mission-critical anomalies.

Enhancing Design and Testing Methodologies

The incident also emphasized the need for more robust material characterization and modeling. The unexpected behavior of the sunshield cables and membranes highlighted the limitations of even advanced material science when applied to the unique conditions of space. Future designs will benefit from an even deeper understanding of how materials perform under sustained microgravity, extreme temperature gradients, and radiation exposure. Furthermore, the development of adaptive deployment software, which can compensate for minor variations and environmental factors, represents a significant step forward.

- Comprehensive Thermal Vacuum Testing: Replicating in-space conditions more accurately.

- Advanced Material Characterization: Deeper understanding of material behavior in space.

- Adaptive Deployment Systems: Software with real-time feedback and adjustment capabilities.

- Interdisciplinary Collaboration: Fostering a broader exchange of expertise from early design.

The “A-Team” approach, characterized by rapid response, multidisciplinary expertise, and streamlined communication, is another vital lesson. When confronted with a mission-critical problem, the ability to quickly assemble a dedicated group of top experts, free from bureaucratic inertia, proved essential. This model of crisis management and problem-solving is likely to be replicated for future complex endeavors, ensuring that the best minds are brought to bear on the most challenging issues. The experience also reinforced the value of designing systems with built-in redundancies and operational flexibility, allowing for adjustments during deployment like those skillfully executed for the sunshield.

The tale of the JWST’s sunshield flaw is not one of failure, but of remarkable resilience and profound learning. It stands as a powerful testament to the ingenuity of NASA engineers and provides a clear blueprint for engineers and scientists embarking on the next generation of ambitious space missions. The knowledge gained from this untold story will undoubtedly contribute to the success of countless future explorations, enabling humanity to continue its quest to understand the universe.

The Enduring Legacy: JWST’s Unprecedented Discoveries

The triumph over the sunshield design flaw was not merely a technical achievement; it unlocked the potential for the James Webb Space Telescope to fulfill its extraordinary scientific promise. Since its full deployment and calibration, JWST has delivered images and data of unprecedented clarity and depth, fundamentally reshaping our understanding of the cosmos. Its capacity to observe in infrared light has allowed it to penetrate cosmic dust, revealing previously hidden nurseries of stars, distant galaxies, and intricate details in the atmospheres of exoplanets. The insights gained are profound, impacting multiple branches of astrophysics and astronomy.

From confirming the existence of some of the earliest galaxies formed after the Big Bang to detecting water vapor and other molecules in the atmospheres of distant exoplanets, JWST’s discoveries are consistently pushing the boundaries of scientific knowledge. It has provided stunning new views of familiar celestial objects, like the Pillars of Creation and the Stephan’s Quintet, but with a level of detail and scientific richness that Hubble simply could not achieve. These images are not just beautiful; they are data-rich scientific instruments, providing clues to the universe’s origins, evolution, and potential for life beyond Earth.

Transforming Our Understanding of the Cosmos

The telescope’s ability to “see” back in time to the early universe has been particularly transformative. By observing the faint infrared light from galaxies billions of light-years away, JWST is giving scientists a direct look at the early stages of cosmic evolution. This includes identifying galaxies that are unexpectedly bright and massive for their age, challenging existing models of galaxy formation and evolution. The data from JWST is sparking new theories and prompting scientists to revisit fundamental questions about the universe’s initial conditions.

- Early Galaxy Observations: Revealing insights into cosmic dawn and galaxy formation.

- Exoplanet Atmosphere Characterization: Detecting molecules that could indicate habitability.

- Star and Planet Formation: Peering into dusty nurseries where young stars and planets form.

- Solar System Studies: Unprecedented views and data from objects within our own solar neighborhood.

Furthermore, JWST is providing critical data for the search for life beyond Earth. Its detailed analyses of exoplanet atmospheres are allowing scientists to identify chemical signatures that could be indicative of biological processes. While definitive signs of extraterrestrial life remain elusive, JWST is providing the tools to narrow down the search and prioritize targets for future, even more advanced, telescopes. Its legacy is not just in the images it produces, but in the paradigm shifts it instigates within the scientific community.

The true measure of the engineers’ triumph over the sunshield flaw lies in the scientific bounty that JWST is now delivering. Their perseverance and ingenuity ensured that this extraordinary instrument could fulfill its mission. The James Webb Space Telescope stands as a beacon of human innovation, a testament to what can be achieved when challenging obstacles are met with unwavering dedication, expertise, and a collective commitment to expanding the horizons of human knowledge. Its discoveries are a direct result of overcoming those critical design challenges, transforming a potential setback into a foundational achievement for cosmology.

The Human Element: Perseverance and Dedication

Behind every triumphant space mission lies a story of human perseverance, and the struggle to overcome the James Webb Space Telescope’s sunshield design flaw is a quintessential example. It was not merely a technical challenge; it was a deeply human one, testing the resolve, ingenuity, and collaborative spirit of hundreds of engineers, scientists, and support staff. The pressure was immense, the stakes incredibly high, and the path to a solution fraught with uncertainty. Yet, the team never wavered.

The “insider knowledge” of this tale illuminates the profound dedication that underpins such monumental projects. Many engineers dedicated decades of their careers to JWST, effectively making it their life’s work. When the critical flaw emerged, these individuals didn’t just see a technical problem; they saw a threat to their shared dream. Their response was not one of despair, but of intensified commitment. They worked tirelessly, often seven days a week, conducting countless tests, running simulations, and brainstorming solutions, driven by an almost palpable sense of duty to the mission and to scientific progress.

The Culture of Problem-Solving

What allowed this team to succeed was not just individual brilliance, but a deeply ingrained culture of problem-solving. This culture fosters open communication, where every idea is heard, peer review is rigorous, and mistakes are seen as opportunities for learning rather than failure. It is a culture that prioritizes meticulous attention to detail and encourages pushing the boundaries of what is known and achievable. This environment was crucial in dissecting the complex sunshield problem and devising a novel, effective solution.

- Unwavering Commitment: Long-term dedication to the mission’s success.

- Collaborative Spirit: Seamless interdisciplinary teamwork and open communication.

- Resilience in Adversity: Ability to adapt and innovate under extreme pressure.

- Meticulous Attention to Detail: Essential for complex, one-shot deployments.

Anecdotes from inside the project reveal moments of frustration, moments of breakthrough, and moments of shared triumph. Engineers often speak of the emotional roller coaster of developing something so complex that it has never been attempted before. The successful deployment of the sunshield was not just a technical validation; it was a profound human victory, a culmination of years of tireless effort, sacrifice, and belief in the impossible. For the teams involved, it was more than just a job; it was a passion, a shared purpose that bound them together and enabled them to overcome what seemed like insurmountable odds.

The untold story of the James Webb Space Telescope’s critical design flaw is, at its heart, a narrative about the human capacity for ingenuity, teamwork, and sheer willpower. It’s a powerful reminder that even with the most advanced technology, it is the human element—the perseverance and dedication of individuals—that ultimately drives scientific discovery and pushes the boundaries of exploration. The legacy of JWST’s engineers is not just in the telescope itself, but in the enduring inspiration their story provides to future generations of problem-solvers.

| Key Point | Brief Description |

|---|---|

| 🚀 Critical Flaw Unveiled | Sunshield tensioning issue threatened JWST’s thermal stability. |

| 🛠️ Expert Task Force | Multidisciplinary teams converged to diagnose and fix the problem. |

| 💡 Innovative Solutions | Adaptive deployment algorithms and thermal compensation devised. |

| 🌟 Enduring Legacy | Flaw resolution enabled JWST’s unprecedented scientific discoveries. |

Frequently Asked Questions About the JWST Design Flaw

▼

The critical design flaw identified in the JWST specifically related to its complex, five-layer sunshield. Engineers discovered an unexpected slack and bunching in the tensioning cables responsible for pulling the sunshield layers taut. This issue threatened the sunshield’s ability to fully deploy and achieve the precise temperatures needed for the telescope’s instruments, thereby jeopardizing its entire mission.

▼

The flaw was unveiled during extensive ground testing, particularly in thermal vacuum chamber tests designed to simulate the harsh conditions of space. Engineers observed the unexpected slack in the sunshield’s cabling system during these deployment simulations. The difficulty in perfectly replicating zero-gravity and extreme temperatures on Earth made the diagnosis particularly challenging, requiring meticulous analysis of subtle environmental interactions.

▼

NASA and its primary contractor, Northrop Grumman, assembled an elite, multidisciplinary task force to address the flaw. This “A-Team” comprised top engineers, material scientists, and thermal experts from various backgrounds. Their collaborative efforts, intense intellectual sparring, and streamlined communication channels were crucial to diagnosing the problem and developing a viable solution under immense pressure.

▼

Engineers implemented several innovative solutions. Key among these was an updated adaptive tensioning algorithm for the deployment motors, allowing for precise control and pauses. They also made minor modifications to cable routing to reduce friction and devised a method to temporarily warm specific sunshield cables to induce controlled expansion, helping them settle correctly before contracting to pull the sunshield taut.

▼

Overcoming the sunshield flaw was absolutely critical to JWST’s success because a properly deployed and tensioned sunshield is essential for the telescope to reach and maintain its cryogenic operating temperatures. Without these temperatures, its infrared instruments would be blinded by their own heat. The successful resolution allowed JWST to begin its scientific mission, leading to its unprecedented astronomical discoveries.

Conclusion

The journey of the James Webb Space Telescope from concept to cosmic observer is a remarkable saga of human ingenuity and unwavering resolve. The untold story of how NASA engineers overcame a critical design flaw in its sunshield is not merely a subplot, but a defining chapter that underscores the very nature of ambitious scientific endeavors. This arduous process, marked by rigorous analysis, innovative problem-solving, and immense pressure, stands as a powerful testament to the capabilities of collaborative engineering. It reveals that the path to groundbreaking discovery is often paved with unforeseen challenges, each serving as an opportunity for profound learning and growth. The perseverance of these dedicated teams not only safeguarded a multi-billion dollar mission but also provided invaluable lessons that will undoubtedly shape the future of space exploration, proving that even the most complex hurdles can be overcome with a combination of expertise, dedication, and an unyielding commitment to pushing the boundaries of human knowledge.